- Equipment

- >

- Ceramic Kilns

- >

- Types of Controllers

Which controller is right for you?

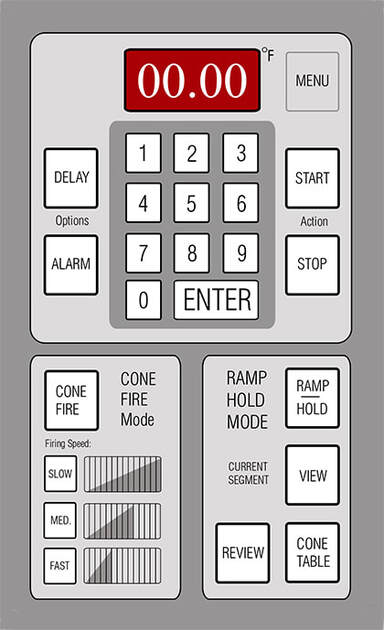

KilnMaster (KM)The KilnMaster controller has long been considered the standard of the industry. This controller comes has most of the features available on the new KilnMaster Touchscreen controller but does not include WiFi, an App for remote viewing, or Help Screens.

|

ConeFire Mode

With ConeFire Mode you just enter 4 pieces of data Preheat Time, Cone Value, Firing Speed, and Peak Temperature Hold Time. The controller then chooses a program for you that was designed by ceramic engineers for optimum results. It even has Cone Correlation built in that will adjust your ending temperature up or down based on the kilns performance to ensure the perfect amount of heatwork. The Preheat feature gives you the option to preheat your unfired pieces to make sure there is no residual moisture in the clay that can cause damage to the ware. You can even turn on a feature now that lets you add a slow cooling ramp to your firing schedule that produces interesting glaze effects. It is appropriately named the COOL feature.

Ramp And Hold Mode

Ramp/Hold mode lets you design your own firing programs of up to 32 segments. Each segment can include temperature rate, end temperature and holding time. You can store up to 12 profiles for easy recall. These capabilities are essential for potters, glass fusers, enamellists and jewelers. For example, it is now easy to program crystal glaze pottery firings which require long, precise soaks while cooling. You can now benefit from the Cone Correlation feature previously only found in ConeFire Mode by pressing the Cone Table key when asked to enter your peak temperature. This allows you to enter a cone value instead of temperature. The controller will then adjust the ending temperature down automatically to ensure proper heatwork no matter how slow your kiln is firing.

Delay Start

Delay start was developed for people who want to fire overnight but do not want to get up in the middle of the night to ensure their kiln shut off okay. You just enter a delay time and the controller will begin counting down the time entered. When it reaches zero it will start the program you have entered.

Temperature Alarm

The temperature alarm can be convenient if there are specific temperatures at which you wanted to be alerted. For example, you may want to set it for 1000F to remind you to lower your lid if you are venting a kiln without a downdraft vent.

Calculate Firing Costs

Yes really! This controller will tell you how much your firing cost you after every firing. All you need to do is follow the manual instructions for entering your cost per Kilowatt hour and the wattage rating of your kiln.

Tracks Total Number Of Firings

Being able to track the number of firings is extremely valuable when you are keeping a kiln log. It allows you to record whenever you change elements, relays and thermocouples. This way you can better predict when you might be ready for some maintenance. It will give you this value after every firing.

Automatically Start Vent

The controller has an additional output on the circuit board which allows you to connect to our EnviroLink. The EnviroLink is an optional accessory that works in conjunction with the EnviroVent 2. When installed it will automatically start the vent when you press start and turn it off when the kiln has cooled to 150F.

Fire In Fahrenheit Or Celsius

Set the display to read in Fahrenheit or Celsius.

Built-In Cone Table

A convenient Cone Table button is available for reference to find the temperatures associated with various cone values.

Best Diagnostics

Skutt is one of the only companies that installs a Current Sensor in the control box. This allows us to test the electrical performance of your kiln without even having to open the box. We can walk you through it on the phone and get all the information we need to diagnose your kiln and get you up and running again.

Voltage Test

Amperage Test

Error Temperature

Board Temperature

Much more…

With ConeFire Mode you just enter 4 pieces of data Preheat Time, Cone Value, Firing Speed, and Peak Temperature Hold Time. The controller then chooses a program for you that was designed by ceramic engineers for optimum results. It even has Cone Correlation built in that will adjust your ending temperature up or down based on the kilns performance to ensure the perfect amount of heatwork. The Preheat feature gives you the option to preheat your unfired pieces to make sure there is no residual moisture in the clay that can cause damage to the ware. You can even turn on a feature now that lets you add a slow cooling ramp to your firing schedule that produces interesting glaze effects. It is appropriately named the COOL feature.

Ramp And Hold Mode

Ramp/Hold mode lets you design your own firing programs of up to 32 segments. Each segment can include temperature rate, end temperature and holding time. You can store up to 12 profiles for easy recall. These capabilities are essential for potters, glass fusers, enamellists and jewelers. For example, it is now easy to program crystal glaze pottery firings which require long, precise soaks while cooling. You can now benefit from the Cone Correlation feature previously only found in ConeFire Mode by pressing the Cone Table key when asked to enter your peak temperature. This allows you to enter a cone value instead of temperature. The controller will then adjust the ending temperature down automatically to ensure proper heatwork no matter how slow your kiln is firing.

Delay Start

Delay start was developed for people who want to fire overnight but do not want to get up in the middle of the night to ensure their kiln shut off okay. You just enter a delay time and the controller will begin counting down the time entered. When it reaches zero it will start the program you have entered.

Temperature Alarm

The temperature alarm can be convenient if there are specific temperatures at which you wanted to be alerted. For example, you may want to set it for 1000F to remind you to lower your lid if you are venting a kiln without a downdraft vent.

Calculate Firing Costs

Yes really! This controller will tell you how much your firing cost you after every firing. All you need to do is follow the manual instructions for entering your cost per Kilowatt hour and the wattage rating of your kiln.

Tracks Total Number Of Firings

Being able to track the number of firings is extremely valuable when you are keeping a kiln log. It allows you to record whenever you change elements, relays and thermocouples. This way you can better predict when you might be ready for some maintenance. It will give you this value after every firing.

Automatically Start Vent

The controller has an additional output on the circuit board which allows you to connect to our EnviroLink. The EnviroLink is an optional accessory that works in conjunction with the EnviroVent 2. When installed it will automatically start the vent when you press start and turn it off when the kiln has cooled to 150F.

Fire In Fahrenheit Or Celsius

Set the display to read in Fahrenheit or Celsius.

Built-In Cone Table

A convenient Cone Table button is available for reference to find the temperatures associated with various cone values.

Best Diagnostics

Skutt is one of the only companies that installs a Current Sensor in the control box. This allows us to test the electrical performance of your kiln without even having to open the box. We can walk you through it on the phone and get all the information we need to diagnose your kiln and get you up and running again.

Voltage Test

Amperage Test

Error Temperature

Board Temperature

Much more…

KilnMaster Touchscreen (KMT)Like Your Smartphone, the new KMT controller navigates with just a touch of a finger and allows us to guide you through programming with full sentences, helpful icons, and dynamic navigation.

Built-in WiFi makes it possible to download any software feature upgrades for free so it is like having a new Kiln Controller for the life of the kiln. A Free App works in conjunction with the WiFi and allows you to monitor your kiln temperature and status from your smartphone. Think how comforting it will be not to get out of bed to be sure your kiln shut off as expected. |

The Hinged Controller allows you to move the controller up and down to an angle that is comfortable for you to program. No more getting on your hands and knees. After programming you can push it back down so it is out of your way and easy to view from across the room.

It has the Same Functions you have come to know and love from the standard KilnMaster Controller Plus More!

There are exciting New Functions that are on this controller as well:

It has the Same Functions you have come to know and love from the standard KilnMaster Controller Plus More!

- ConeFire Mode – Allows you to easily program the kiln based on the cone value and whether it is a bisque or glaze firing. Now it is faster than ever. An easy to edit screen lets you quickly change parameters from the last firing and start the program. You can also view the actual segments in the program and display a graph of the firing.

- Ramp/Hold Programming Mode – Allows you to easily input your own firing programs. Now you can Name Your Programs and store them in My Programs for easy access. You can even Copy Programs you like, but want to change slightly to speed up the programming process.

There are exciting New Functions that are on this controller as well:

- Guided Start – This programming Mode is meant for beginners. It guides you through every step of the programming process with Helpful Messages to make things crystal clear and give you confidence you have done everything correctly before you press Start.

- Program Library – We have added a program library with helpful programs for unique processes like Slow Sculpture, Steven Hill Single Fire, and Cone 5 Crystal Glaze.

- Help Screens – Nearly every page has a Help Button that will give you detailed information about the screen you are currently viewing. It is like having the manual right on the controller!

- More Detailed Diagnostics – We put in place more detailed diagnostic tools which make it faster to figure out what may be going on with your kiln. And, because your kiln is connected to the internet our technicians can view the data right from their desk.

- Graphing – When you press Start the controller will display a Graph of the firing so you can follow it along as the kiln goes through the program.

- Logging – The controller actually stores the information from your last 10 firings which can be downloaded to an Excel Spreadsheet.

- Upgrading to KilnLink – Adding KilnLink to your kiln just got easier and more affordable. The built-in WiFi eliminates the need for expensive hardware so now all you need to do is pay a minimal monthly data storage and development fee.