- Equipment

- >

- Ceramic Kilns

- >

- Why Choose Skutt?

Why choose Skutt?

There are plenty of other well-known brands out there, so why does Armadillo only carry Skutt kilns? Well, we've been been around the block a time or two (or forty!) and of all the companies we've worked with, we have yet to find a single bad thing to say about these guys - or the kilns they build.

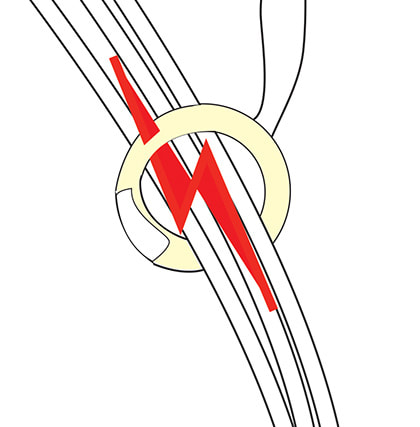

Current SensingTraditionally, when your kiln is not firing correctly, it is necessary to open the control box and take some electrical readings to diagnose the problem. Since most people do not have the test equipment or are not qualified to take live electrical readings from a kiln, this usually requires hiring a trained technician to come out and diagnose the problem. This can take time to schedule and cost a significant amount of money.

Skutt is one of the few companies that installs that technician right in the kiln in the form of a Current Sensor. A current sensor is a small donut shaped device that can read current (Amperage) when one leg of a circuit is passed through it. |

Being able to sense current is one of the best tools for diagnosing your kiln and this tool is accessed easily from the Menu key on your controller. This allows you to provide your service technician the information he or she needs without having to make an additional service call. This way they can order the needed parts and come out once to install them.

The circuit board can also check the voltage supply powering the kiln. It firsts checks against where the kiln is drawing power. This will tell you if the supply matches the voltage for which the kiln was designed. It then measures the voltage with the kiln on. This can indicate problems with the electrical installation from the breaker box to the outlet. If the voltage drops significantly when the kiln is turned on it can be an indication that the wire gauge is not adequate given the draw of the kiln or the distance from the breaker box to the outlet.

The circuit board can also check the voltage supply powering the kiln. It firsts checks against where the kiln is drawing power. This will tell you if the supply matches the voltage for which the kiln was designed. It then measures the voltage with the kiln on. This can indicate problems with the electrical installation from the breaker box to the outlet. If the voltage drops significantly when the kiln is turned on it can be an indication that the wire gauge is not adequate given the draw of the kiln or the distance from the breaker box to the outlet.

Sectional Design

Skutt was the pioneer of sectional kiln building over 50 years ago. That means they've had 50 years to perfect sectional design. Many have copied this design due to it’s popularity but none can match Skutt's quality. The sectional design allows the owner to quickly disassemble the kiln for moving or repair. This design brought ceramics into the home. Its light weight coupled with the ability to break down into smaller sections made it possible to move a kiln through a narrow doorway or down a flight of stairs.

With a sectional kiln you can get right to the part you need to replace. The hinged control box was designed to give you quick access to replacing the thermocouple without needing to balance the box on your leg. It also comes completely off to allow you to separate the sections. The wires that attach to the box are numbered and connected with slide on connectors. These provide a secure fit but also make removing and replacing them a snap. Once the sections are apart you can access any brick or element without having to crawl into your kiln.

With a sectional kiln you can get right to the part you need to replace. The hinged control box was designed to give you quick access to replacing the thermocouple without needing to balance the box on your leg. It also comes completely off to allow you to separate the sections. The wires that attach to the box are numbered and connected with slide on connectors. These provide a secure fit but also make removing and replacing them a snap. Once the sections are apart you can access any brick or element without having to crawl into your kiln.

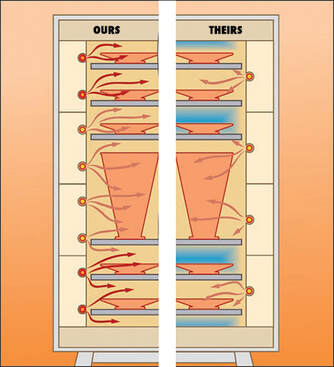

Balanced Elements

Nearly all Skutt kilns have Computer Balanced Elements. This means we design the elements so that more heat is put in areas of the kiln that naturally fire cooler. The top and bottom of the kiln lose heat faster than the center so Skutt puts hotter elements (more power) in those areas.

The figure to the right indicates how a kiln with Computer Balanced Elements will take a naturally unbalanced chamber and adjust it to be balanced.

This also has an impact on the efficiency and capability of Zone Control. By balancing the heat in the chamber to start, Zone Control does not have to work as hard. You have less cycling (zones turning on and off to balance the heat) and when the kiln does need to cycle the power, it is distributed efficiently into the areas that need it the most.

The bottom line is money saved on electricity, tighter controls, and faster turn around times.

The figure to the right indicates how a kiln with Computer Balanced Elements will take a naturally unbalanced chamber and adjust it to be balanced.

This also has an impact on the efficiency and capability of Zone Control. By balancing the heat in the chamber to start, Zone Control does not have to work as hard. You have less cycling (zones turning on and off to balance the heat) and when the kiln does need to cycle the power, it is distributed efficiently into the areas that need it the most.

The bottom line is money saved on electricity, tighter controls, and faster turn around times.

Precision Thermocouples

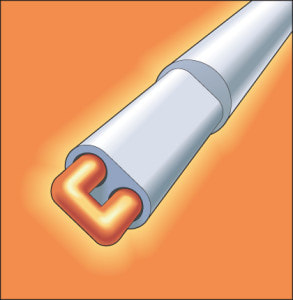

A thermocouple is a component of the kiln used to read the temperature within the kiln chamber. The controller uses the information it receives from the thermocouple and makes decisions on whether or not to turn the element on or off.

The thermocouple is constructed of 2 pieces of dissimilar metal (usually wire) that are joined together at one end. When heated this junction creates a very small electrical signal (measured in millivolts) that changes as the temperature is raised or lowered. Since the signal moves predictably it can be converted by the controller into a temperature reading.

Skutt's exposed thermocouple design provides faster reaction time and higher accuracy. The standard Type K 8-Gauge thermocouple is affordable and extremely easy to replace, and every new Skutt KM or KMT kiln comes with a spare.

The thermocouple is constructed of 2 pieces of dissimilar metal (usually wire) that are joined together at one end. When heated this junction creates a very small electrical signal (measured in millivolts) that changes as the temperature is raised or lowered. Since the signal moves predictably it can be converted by the controller into a temperature reading.

Skutt's exposed thermocouple design provides faster reaction time and higher accuracy. The standard Type K 8-Gauge thermocouple is affordable and extremely easy to replace, and every new Skutt KM or KMT kiln comes with a spare.

Lid LifterThe New Lid Lifter makes Skutt's 10 and 12-sided lids some of the lightest on the market. In fact, you can now lift them with just a finger. The lid brace has been redesigned for added strength and now has 2 positions. The innovative Center Pivot Design distributes the force on the lid across 2 points as opposed to only one. Made from stainless steel with a stay-cool ceramic handle.

It ships fully assembled on the kiln. And unlike some other brands there is no awkward loading of the springs required. The kiln remains completely sectional for moving and repairs. The lid can be effortlessly and safely detensioned by simply raising the lid and sliding out the tension rod. It really is that easy! |

Warranty

The funny thing about warranties is that they are only as good as the support structure behind them. A company could offer a 20-year warranty but when you take into account the exclusions, the waiting for call backs, and your over-all frustration level, what is it really worth? Skutt’s 2 year warranty is straight-forward. If you have a failed component on your kiln within 2 years of purchasing it, Skutt will fix it - parts AND labor. Many of Skutt's full service distributors (including Armadillo Clay) will even repair the kiln on site. Due to the fact that it is possible to exceed the estimated life of a thermocouple before the end of the warranty period, thermocouples are the only items not covered under the warranty.

Customer Service

If we had to choose the one thing we like best about Skutt, it would be their incredible customer service. With 60 years of experience, their family-owned business is staffed with courteous, knowledgeable folks who pick up the phone when you call. Anyone from the biggest distributer to the smallest home hobbyist can call their technical department for help and have a skilled technician guide them through the troubleshooting process.

Contact Skutt

Call: (503) 774-6000

E-mail: [email protected]

Fax: (503) 774-7833

Website: www.skutt.com

Hours: M-F 7:30am - 5pm

Contact Skutt

Call: (503) 774-6000

E-mail: [email protected]

Fax: (503) 774-7833

Website: www.skutt.com

Hours: M-F 7:30am - 5pm