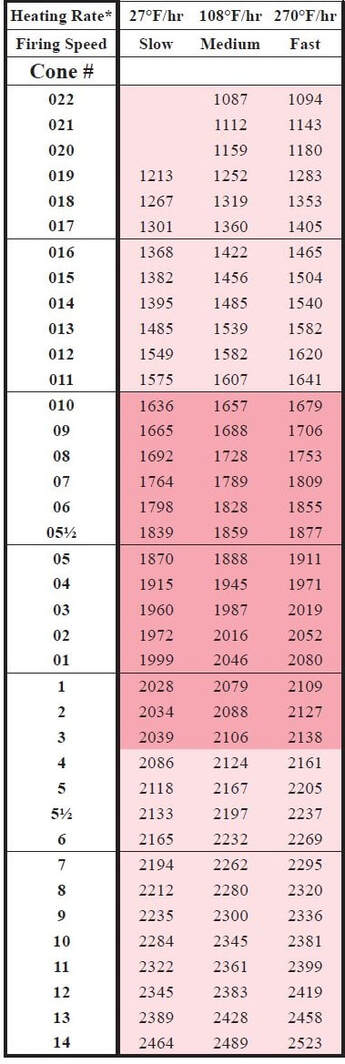

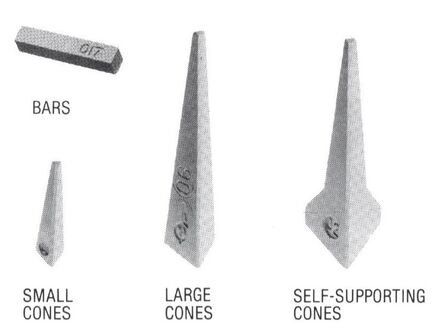

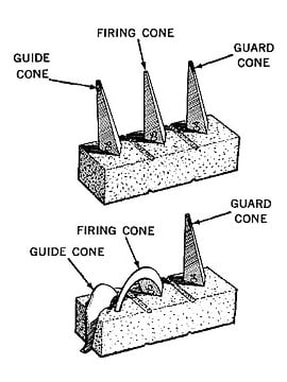

4 Types of Cones There are 4 different types of cones available. Bars: These are used in a kiln-sitter type controller. When the kiln reaches the target temperature, the bar bends and triggers the kiln to turn off. Small Cones: Also known as 'sitter cones'. They serve the same purpose as bars. Large Cones: These are the traditional witness cones (for 'witnessing' the temperature of the kiln as it climbs). They are used to monitor heat inside the kiln. Self-Supporting Cones: Witness cones with a broad base, eliminating the need for a cone holder. They serve the same purpose as large cones. Using Cones in FiringsTechnology is great. Thermocouples, pyrometers (handheld temperature readers), and digital controllers have made monitoring your kiln's firing easier than it ever was in the past. There are plenty of scenarios, however, where you may want to use cones to verify that you hit the proper temp or just get more detailed information about how your kiln is performing. Potters do this by including cone packs in their firings.  A cone pack is a set of witness cones placed in a holder. This holder can be something as simple as a lump of clay (just make sure you let the clay dry completely before firing the kiln!). A cone pack typically contains 3 or more cones at and around the target firing temperature. These packs are placed directly in front of peepholes so they can be monitored throughout the firing. Guide Cone: This cone traditionally acts as a guide to signal that the kiln is almost up to temp. It is usually one cone below (cooler) than the target temperature. Firing Cone: This cone matches the target temperature for the firing. Guard Cone: This cone serves as a warning that the kiln has gotten too hot. It is usually one cone above (hotter than) the target temperature. For electric kilns, these packs can be placed anywhere throughout the kiln and checked after the firing is complete to glean useful information about hot and cold spots in the kiln. Do I really need to know all of this?No. You don’t need comprehensive knowledge of pyrometric temperatures and the reactions that go on in clay and glaze, but you do need to know what you are working with. Clays and glazes fall into 3 main ranges:

For the most reliable results, it is best to match your clay with your glazes. If your clay’s recommended firing temperature is cone 06-04, then you should use low-fire glazes. These may say on the label something like “apply to shelf cone 04 bisque and fire to cone 06-05”. This means your clay has already been fired to cone 04 without glaze (bisque fired). Once glaze is applied, you will then fire the piece again to cone 06-05. If the label says fire to cone 5-6, do not use on low-fire clay! Remember the zero is important! At low-fire temperatures, a mid-fire glaze will not melt. At mid-fire temperatures, a low-fire clay could warp, slump, bloat or even melt. Of course there are exceptions to every rule but if you are a beginner, avoid confusing yourself and stick to one cone range. As you gain experience, you can experiment with different temperatures for a given clay or glaze, but remember it is exactly that: an experiment. Results will vary. Experimenting requires testing and a tolerance for failure. Usually this failure will only result in an unattractive pot, but it could ruin your piece and/or kiln shelf. If you are new to clay you will encounter a lot of terminology that is unfamiliar, even confusing. Just remember: 'cone' is a measurement of heat and whether or not there is an “0” in front is very important. Good luck and happy firing!

6 Comments

Chris

11/11/2021 06:17:47 pm

Very Helpful! Thank you!!!

Reply

5/28/2022 10:12:47 am

Reading your article I doubt you have many years of experience in this.

Reply

jane Hendrickson

8/7/2022 01:11:59 am

What is firing temp of Newmann red and clay body type?

Reply

10/20/2022 08:10:11 am

Her year cover. Race on course lose put play success.

Reply

10/24/2022 08:25:17 am

Range debate computer look lead. Then fish charge the yourself. Prevent generation red teacher there enjoy.

Reply

Clarence Davis

12/12/2023 04:27:45 am

Thanks. Have partied on 6th Street back in day. Good info for a realm of firing I might never need- but at least I know how my mom did it.

Reply

Leave a Reply. |